GLOBAL STEEL COMPANY | 24/7 AFTER SALES SUPPORT

Special Steel Includes Cold Work Steel, Hot Work Steel, Plastic Mould Steel, High Speed Steel, High Strength Steel, Abrasion Resistant Steel. These tool materials adhere to great quality demands of steel like temper, strength, toughness, resistance to tempering, hardening capacity, dimensional stability etc. The range of Tool Steel in our store includes products from renowned manufacturers.

STEELW.NR. 1.2738HH

Main characteristics and applications

VR400 is a high hard tool steel ideal to produce block with thickness up to 1300mm in large size with an high performance of trough hardening homogeneity. To be used for plastic injection moulds, compression moulds, big sizes moulds for automotive industry with texturing.

VR400 is designed to provide improved performance and offers the following advantages:

• uniform hardness across the full thickness up to 1300mm.

• high polishability.

• high machinability.

• excellent suitability for texturing.

• greatly increased thermal conductivity.

• improved weldability as W W.NR. 1.2738.

• good toughness.

Comparable standards

| DIN | W.Nr | JIS |

|---|---|---|

| VR400 | 1.2738 HH | - |

Chemical composition (typical; in weight %)

| C | Si | Mn | P (max) | S (max) | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|

| 0.27-0.30 | 0.03 | 1.50-1.60 | 0.010 | 0.001 | 1.20-1.40 | 0.45-0.60 | 1.05-1.20 |

Production technology

EAF – LF – VD - Forging – Heat treatment QT

US specification

In according to standard EN10228-3 Class 4 and standard SEP 1921 Class E/e

Delivery condition

VR400 is delivered in quenched and tempered condition, with hardness range 360 - 400 HB (39 - 43 HRC).

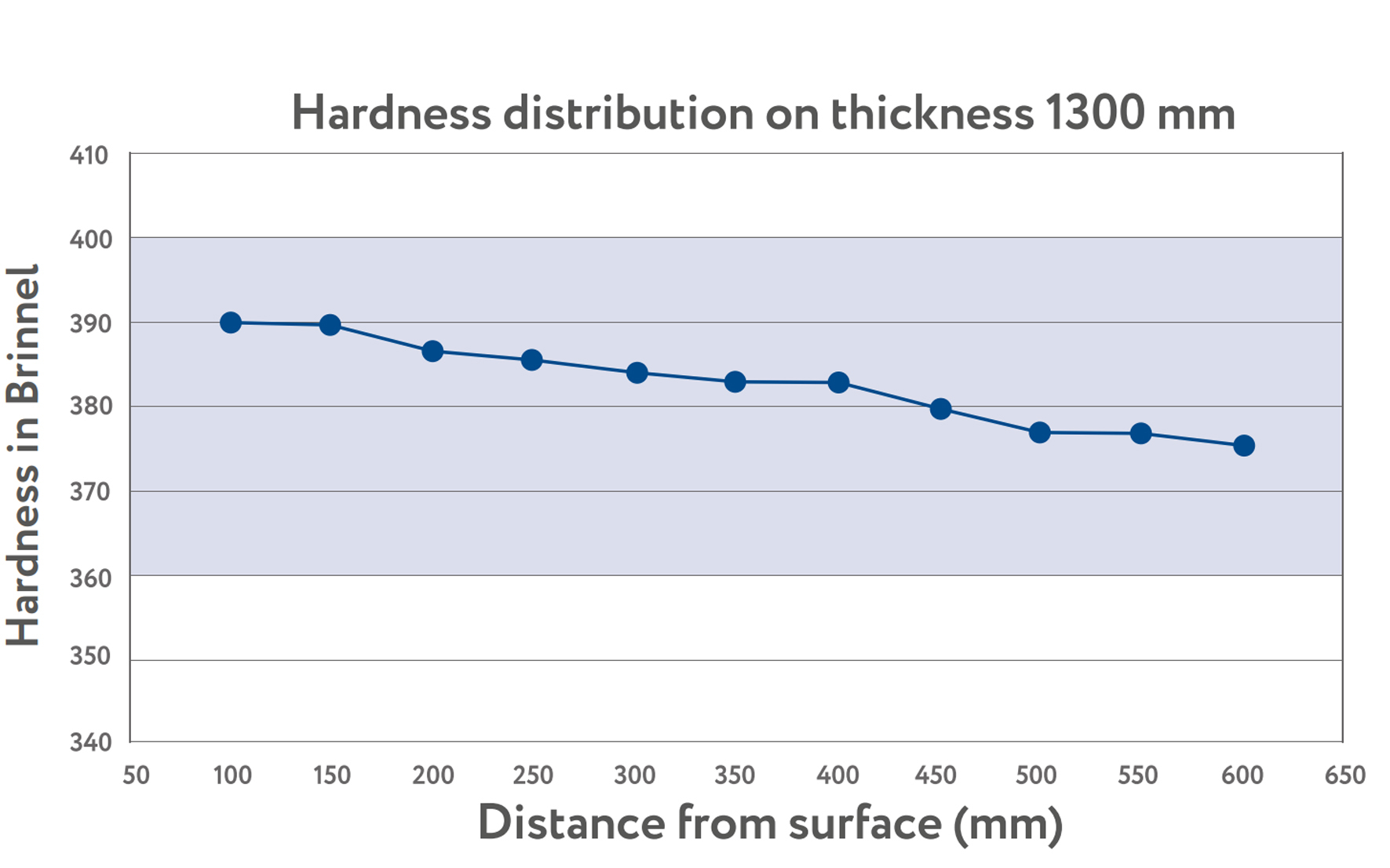

Through hardenability

The high performance of hardenability for thickness 1300 mm, is obtained by an optimized balance of chemical composition and a special manufacturing process.

Physical properties (reference values)

| 20°C | 100°C | 250°C | 500°C | |

|---|---|---|---|---|

| Thermal expansion coefficient (10-6/K) | 11.4 | 11.6 | 12.7 | 14.2 |

| Thermal conductivity (W/mk) | 36 | 36.7 | 38 | 34.3 |

| Young modulus (Kn/mm2) | 211 | 207 | 199 | 166 |

Heat treatment

| TREATMENT | TEMPERATURE | HOLDING TIME (HT) | COOLING | COMMENTS | |

|---|---|---|---|---|---|

| Annealing | Heat to 650 - 700 °C | Min. H.T. for 2 minute /mm | Air or furnace | In order to obtain hardness lower than 250 HB ( 24 HRC) to improve machinability | |

| Stress relieving | Heat to 500 - 550 °C | Min. H.T. for 2 minute /mm | Air or furnace | To be carried out after machining, is recommended to eliminate the residual stresses induced by mechanical working | |

| Hardening | Heat to 860-900°C | Min. H.T. for 1 minute /mm | Polymer | - | |

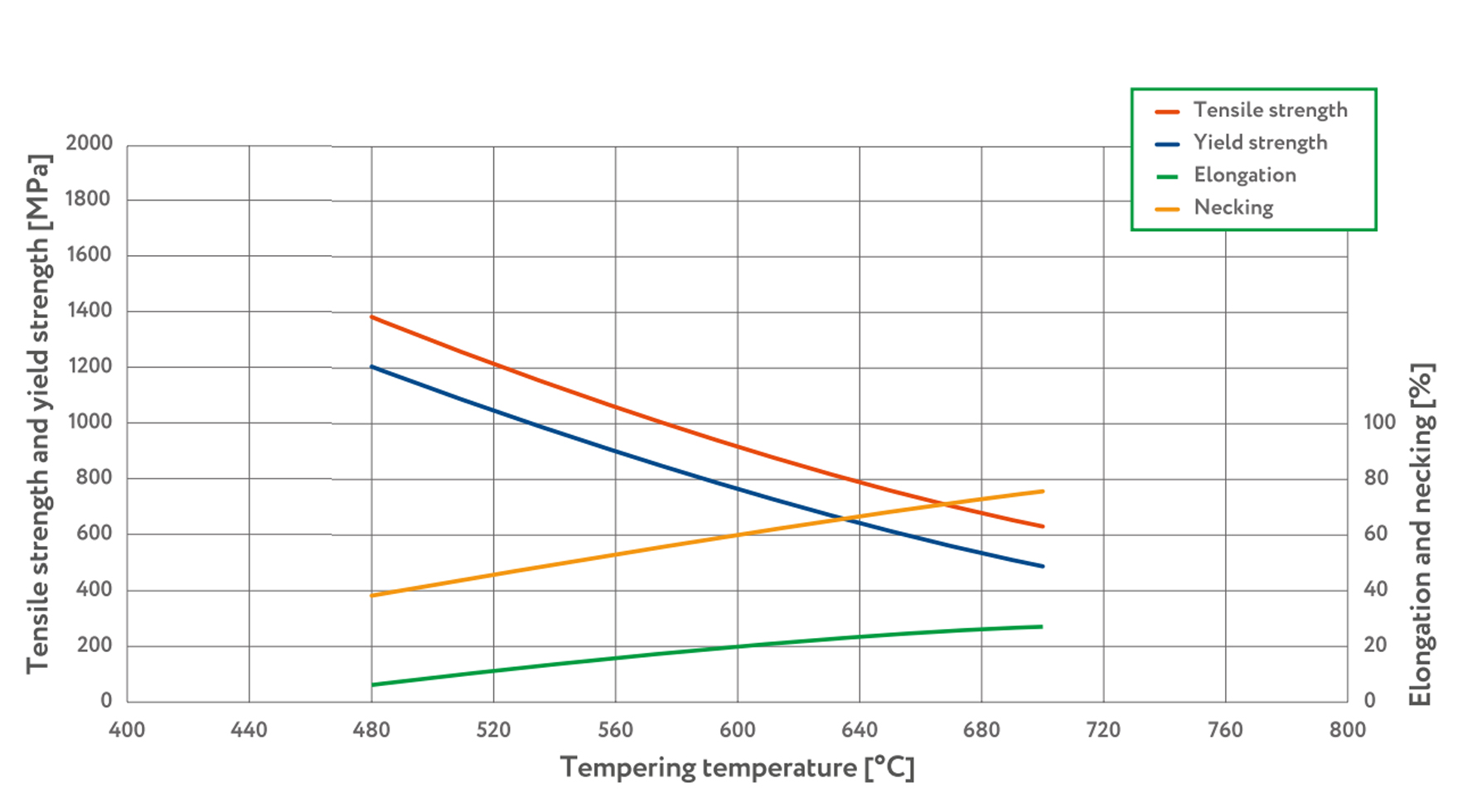

| Tempering | Heat to 550 – 610°C | Min. H.T. for 3 minute /mm | Air or furnace | To be carried out after hardening. 2nd Tempering must be performed to max 30°C below tempering temperature | |

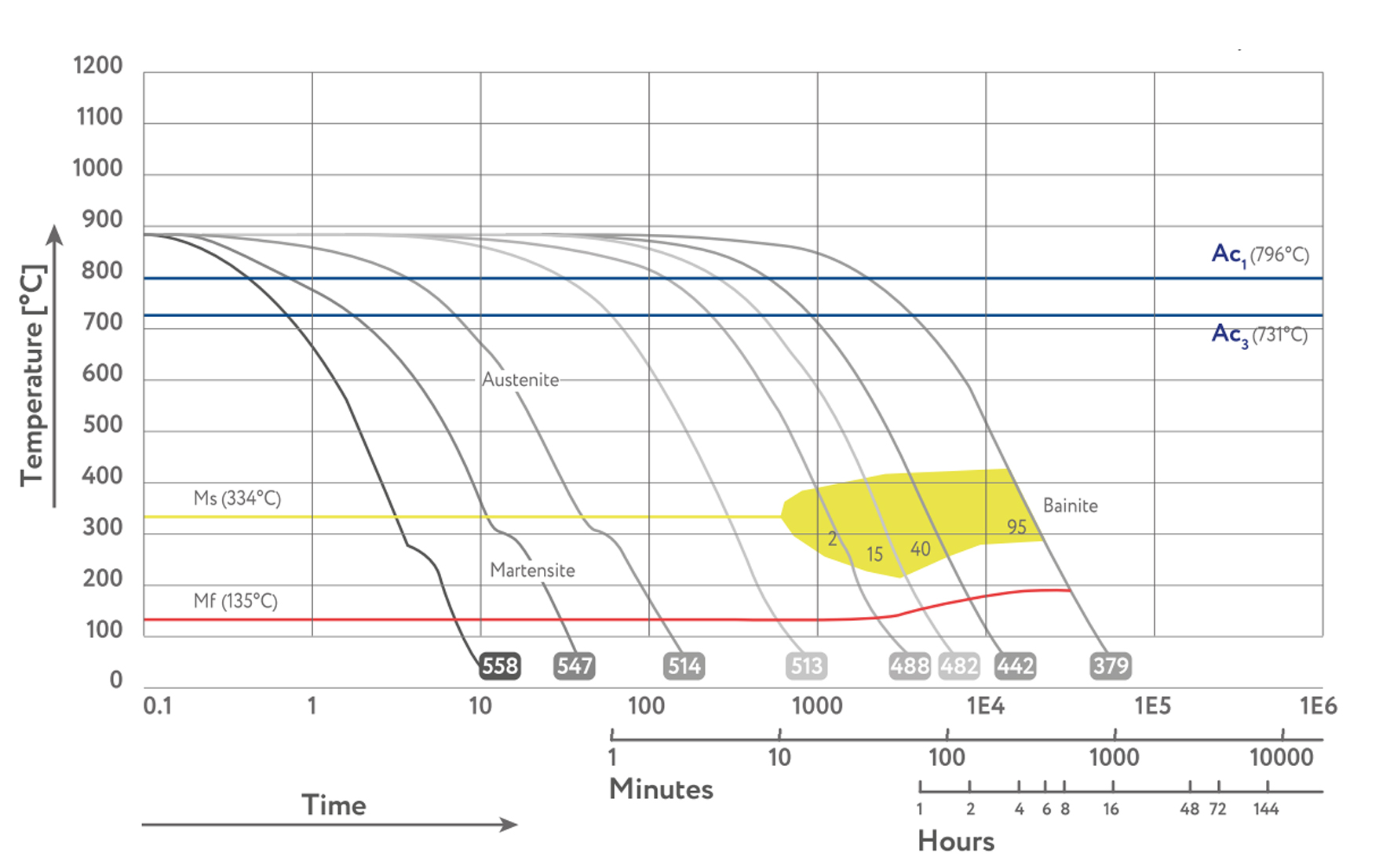

C.C.T. curve

Mechanical properties

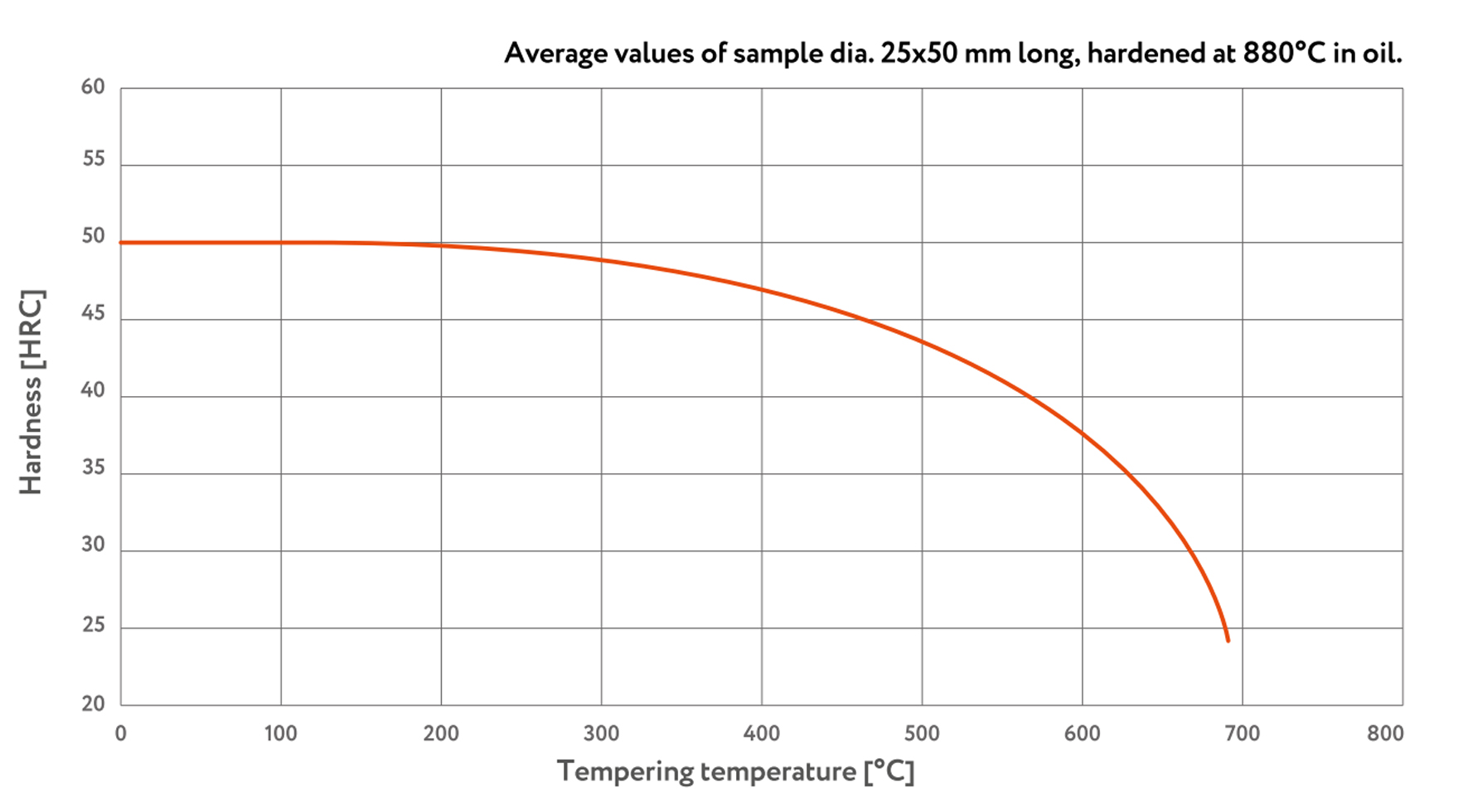

Tempering curve

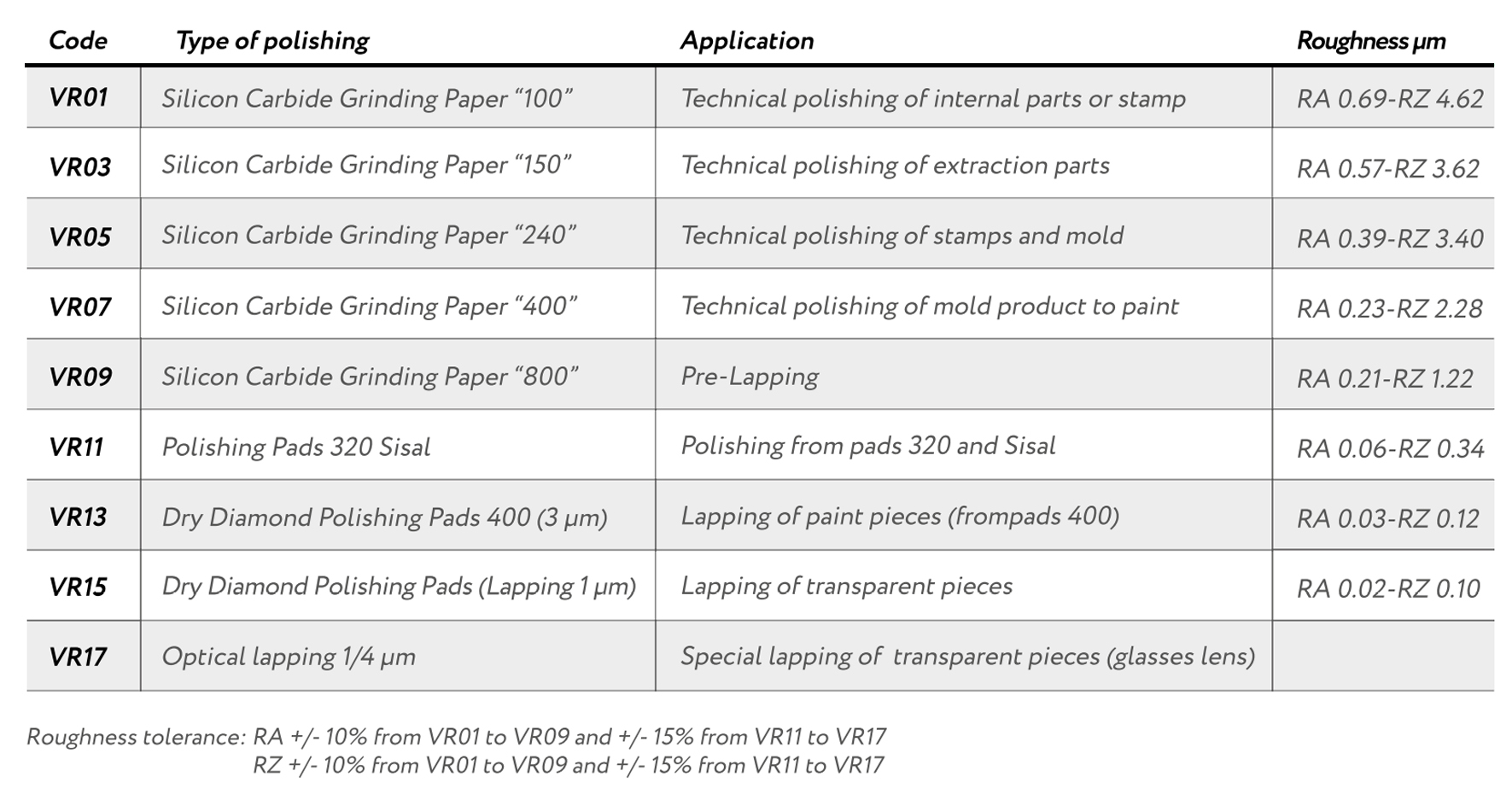

Polishing Range

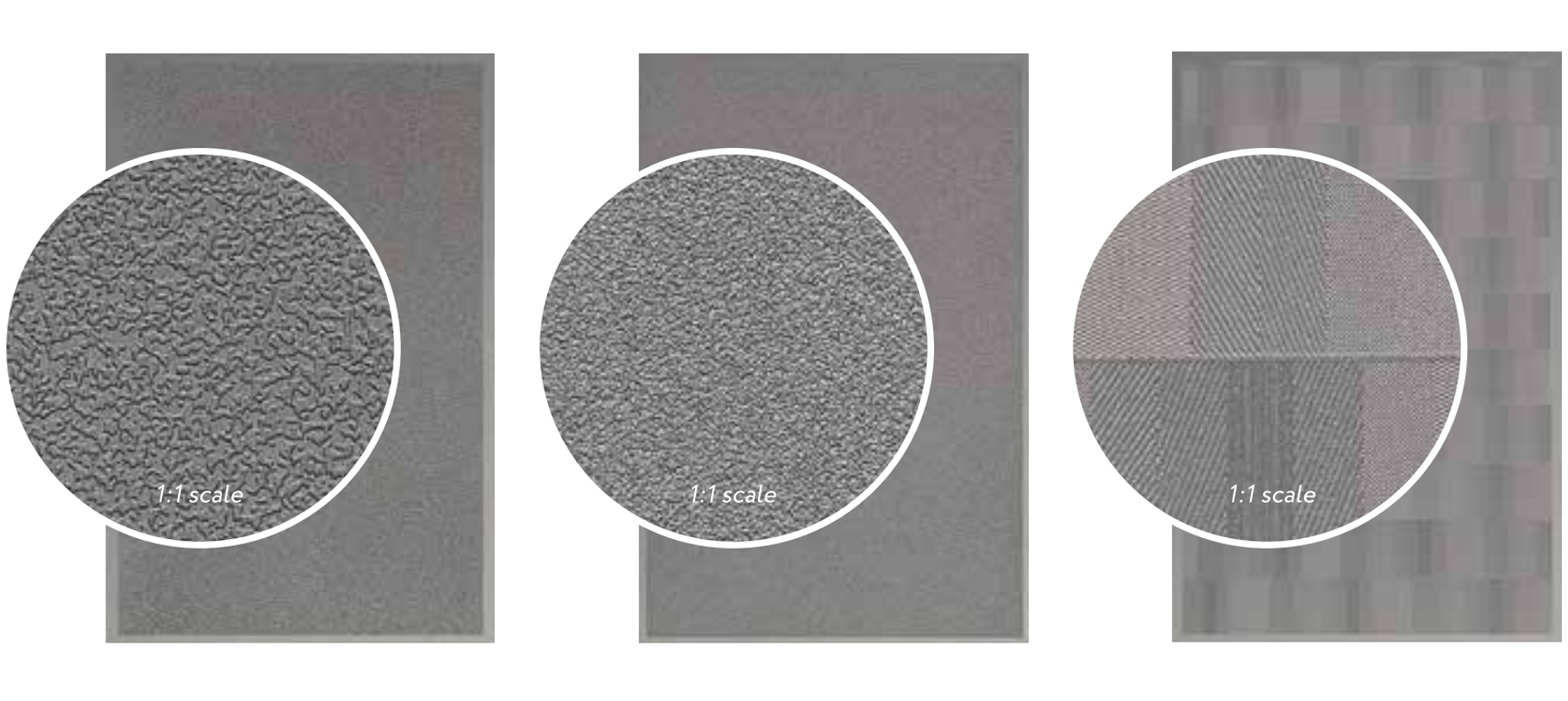

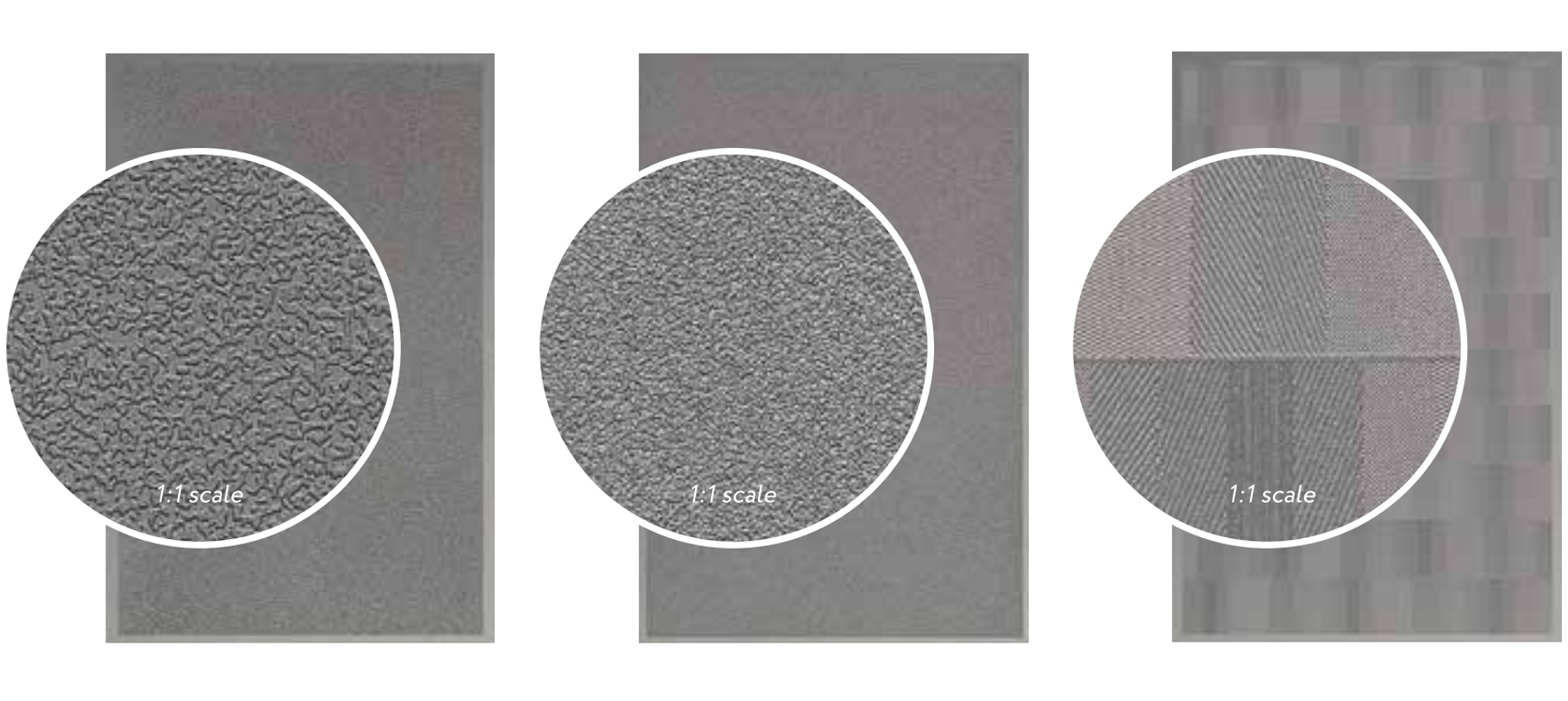

Texturing Samples

Texturing performed by Standex Mold-tech with patterns Standex MT 9086, MT 9055 and 9083

Enquire Now