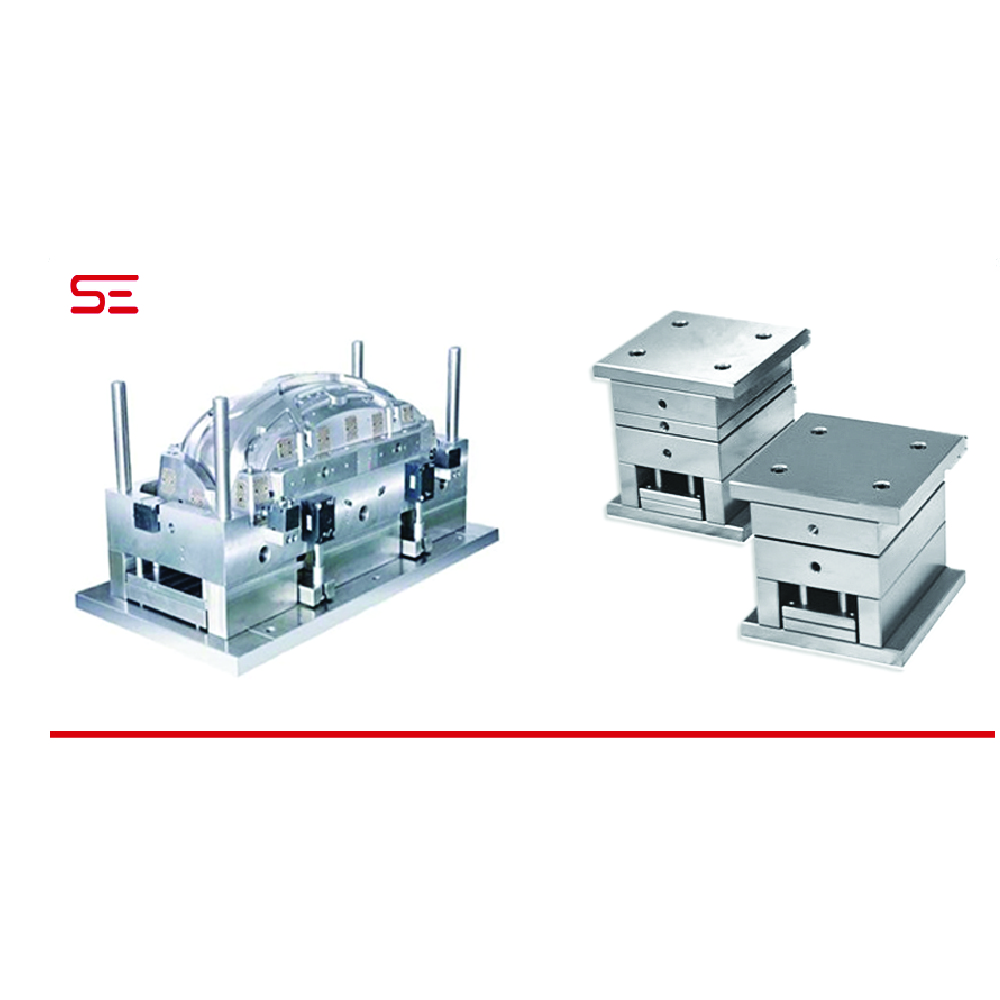

Plastic mould steel, also known as injection molds or tooling, are specialized tools used in the manufacturing process of plastic products. They are typically made from steel or aluminum and are custom-designed to produce specific shapes and dimensions of plastic parts.

The process of plastic molding involves injecting molten plastic material into the mold cavity under high pressure. This process can be repeated many times, allowing for mass production of identical plastic components.

The process of plastic molding involves injecting molten plastic material into the mold cavity under high pressure. This process can be repeated many times, allowing for mass production of identical plastic components.

Plastic mould steel are useful in several ways:

Mass production: Plastic molding enables the efficient and cost-effective production of large quantities of plastic parts. Once a mold is created, it can be used repeatedly to produce identical parts with high precision and consistency.

Versatility: Plastic molds can be designed to produce complex shapes and intricate details that would be difficult or impossible to achieve with other manufacturing processes. This makes them suitable for a wide range of industries, including automotive, electronics, packaging, consumer goods, and more.

Cost-effective: While the initial investment in creating a plastic mold can be significant, the per-unit cost decreases significantly when producing large quantities of parts. This makes plastic molding an economical choice for mass production compared to other manufacturing methods.

Customization: Plastic molds can be customized to meet specific product requirements. Manufacturers can adjust factors such as material composition, part design, surface finish, and color to achieve the desired characteristics and aesthetics for their products.

Efficiency and speed: Plastic molding processes can be highly automated, leading to faster production cycles and shorter lead times. This is especially beneficial when there is a demand for quick turnaround times or tight production schedules.

Versatility: Plastic molds can be designed to produce complex shapes and intricate details that would be difficult or impossible to achieve with other manufacturing processes. This makes them suitable for a wide range of industries, including automotive, electronics, packaging, consumer goods, and more.

Cost-effective: While the initial investment in creating a plastic mold can be significant, the per-unit cost decreases significantly when producing large quantities of parts. This makes plastic molding an economical choice for mass production compared to other manufacturing methods.

Customization: Plastic molds can be customized to meet specific product requirements. Manufacturers can adjust factors such as material composition, part design, surface finish, and color to achieve the desired characteristics and aesthetics for their products.

Efficiency and speed: Plastic molding processes can be highly automated, leading to faster production cycles and shorter lead times. This is especially beneficial when there is a demand for quick turnaround times or tight production schedules.

Overall, plastic molds are essential tools in the plastic manufacturing industry. They enable efficient mass production, offer design flexibility, and contribute to cost-effective manufacturing processes, making them widely used in various industries around the world. Sandeep Enterprises is dedicated to serving our customers by providing a wide range of services. Our offerings include bandsaw cutting, machining, grinding, pre-machined plates with boring, steel component manufacturing, wear liner and bolted plates, as well as custom attachments. We strive to meet the unique needs and requirements of our clients through these comprehensive solutions.